BSE bulk solids engineering

Tel.: +31 53 434 45 66

Print: 20 Feb 2026 17:13

GlossaryExplanation of typical topics in bulk technology

Below is an explanation of a number of important concepts in the field of bulk technology. First of all, an introduction to the substance we call bulk. Then a short explanation of two important flow patterns: mass flow and core flow, and why flow does not always go well: bridging.

ArticlesFor a more detailed explanation of phenomena in the transport and storage of bulk goods, see the articles in the reading_room. Bulk SolidsPowder, solids, dry matter, granular material, bulk material...

Bulk solids do not have an unambiguous name; it is not an unambiguous material. Bulk solids do neither behave as a solid, nor a liquid, nor a gas. A definition of this matter could be: a number of particles that in principal can move freely, but that definitely show interaction and are also influenced by gases and/or liquids that are present between these particles.

Whatever it is called, through fundamental knowledge and years of experience BSE is specialist in the field that we call bulk technology.

Mass flowFIFO: first-in, first-outAdvantages:

Disadvantages:

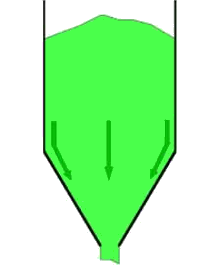

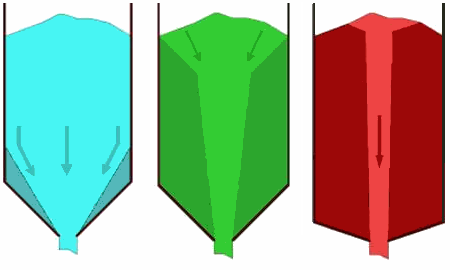

When mass flow occurs, the whole contents of the silo is moving as soon as product is withdrawn from the silo. For more information on mass flow design see silo design. When mass flow does not occur, the flow type in the silo is called core flow, funnel flow or ratholing, see below. Core flow, funnel flow, ratholingSometimes useful, usually undesirableThe type of flow where part of the product in the silo is at rest (stagnant zones) is called funnel flow, core flow or ratholing.

Funnel flow is only applicable for coarse, free flowing products, where ageing or decay is not important. In all other cases mass flow should occur, for the following reasons:

BridgingBulk solids do not flow through every hole

Bridging is one of the most apparent and troublesome problems with silos. It can occur because product particles jam over the opening, but most of the bridging problems occur with powders. Here it is the cohesion, the sticking of particles, that makes the product hang up. Dependent on the circumstances (for example storage time) a stable bridge of a powder can reach span of five metres!

When a product is withdrawn from a silo, it must converge in the hopper. The product is supported by the hopper wall. Arches of product are formed. bridges.gif)

For every situation a critical outlet diameter can be determined. When the outlet of the silo is bigger than this critical diameter, the product will flow from the silo.

The unconfined yield stress of a product depends on: For more information on silo design see document bulk technology. |